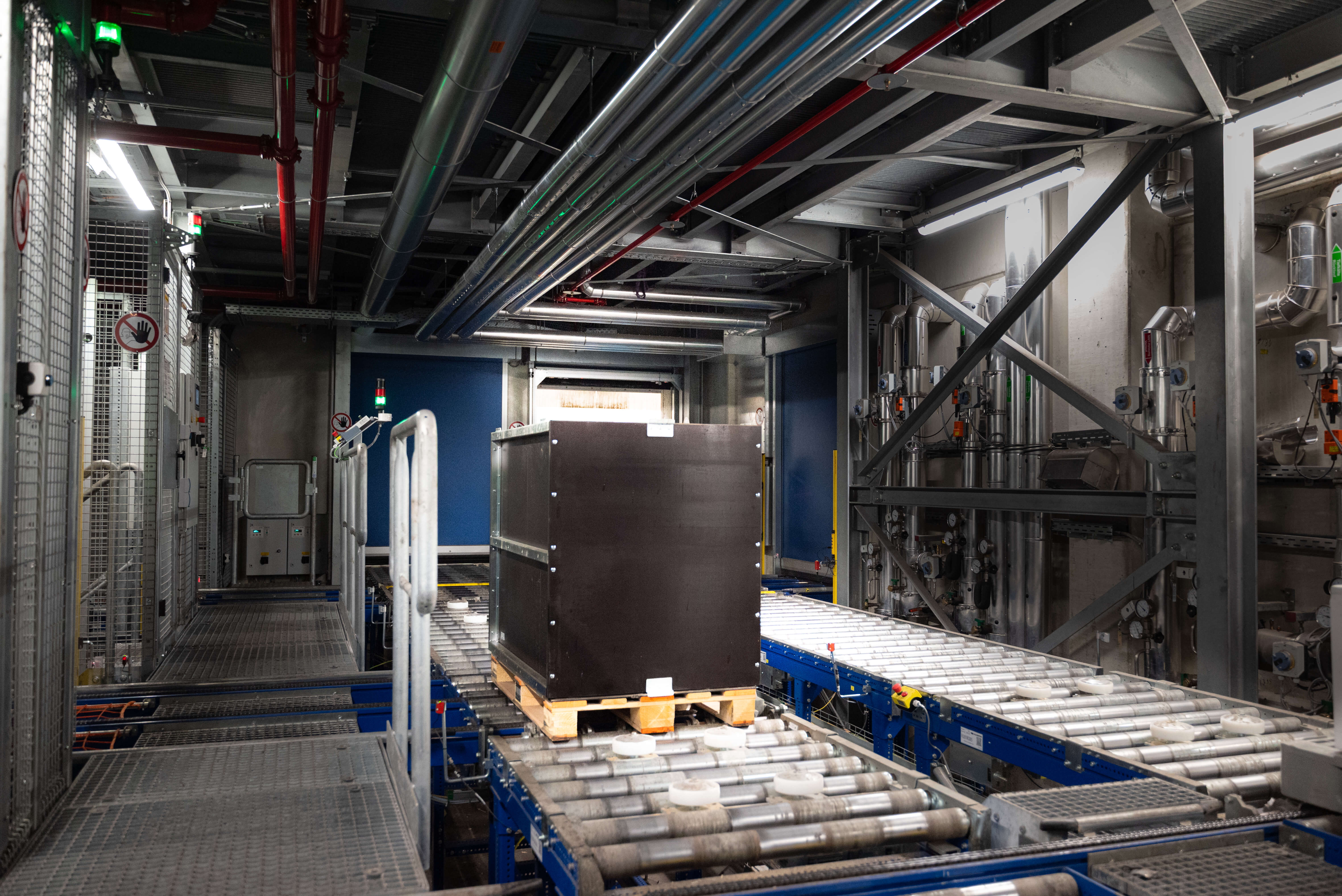

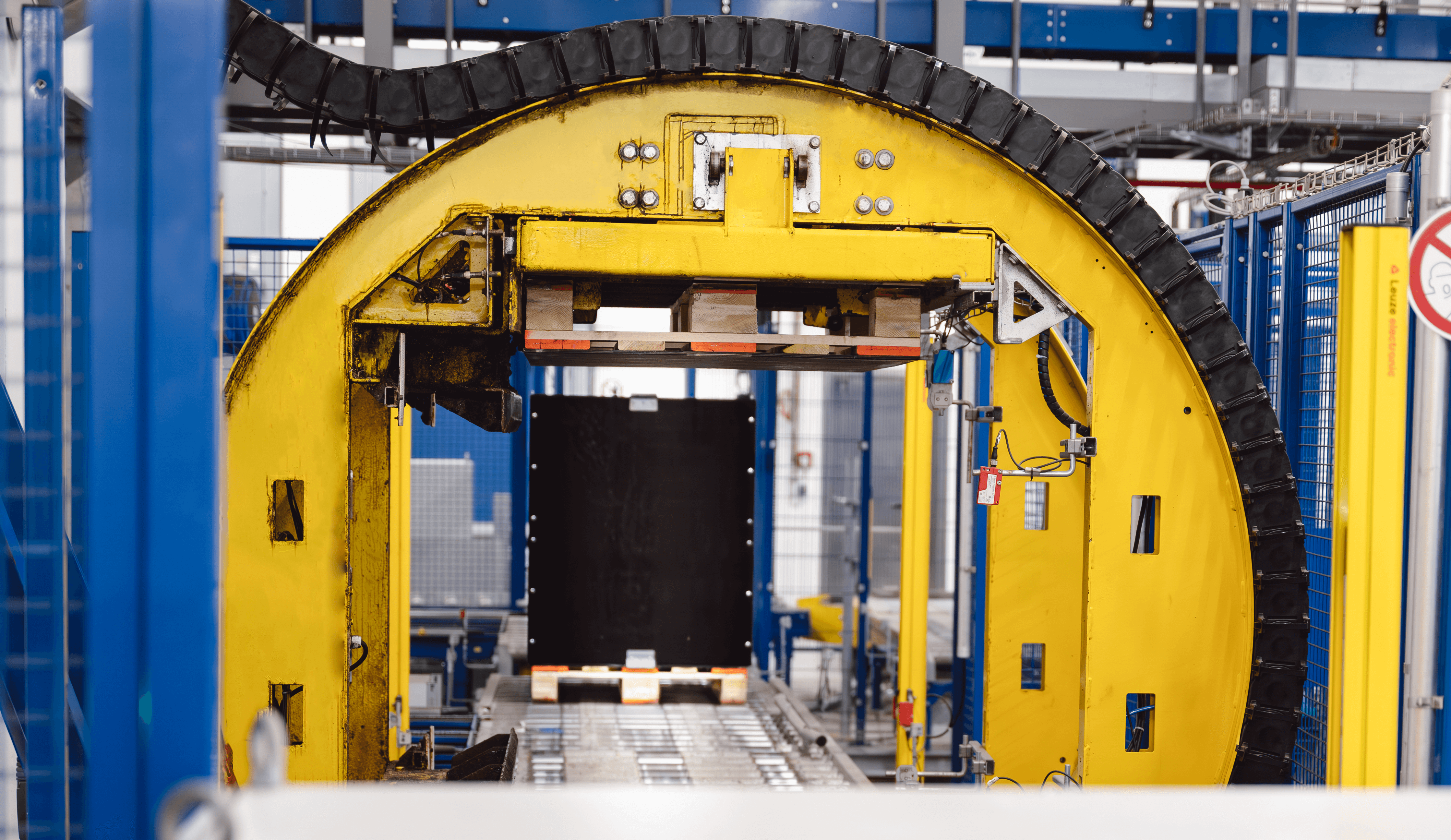

The GEBHARDT cheese ripening containers

By using GEBHARDT cheese ripening containers, you can optimize your existing processes in industrial cheese production and cheese ripening. Expand your capacities and increase your productivity while minimise your waste. The stable reusable system is suitable for automation and can be stacked several times. The structure of the pallets and frames is designed according to customer requirements and is food safe. Learn more about GEBHARDT cheese ripening containers and their advantages.

We will be happy to design the right container for you together with you.

Arrange a consultation appointment